A Complete Guide by SV Interiors Hyderabad In 2025

When it comes to building durable, reliable, and lasting interiors — whether for a modular kitchen, custom furniture, or architectural framework — metal welding plays a critical role. At SV Interiors, Hyderabad’s premier interior and civil design company, we rely heavily on frequently utilized metal welding systems to ensure structural integrity and modern functionality across our projects.

But what exactly are these welding systems? Why are they so essential in residential and commercial interior design? And which systems are most frequently used in the Indian construction and design industry today?

In this comprehensive guide, we break it all down — from types and techniques to advantages, applications, and real-world use cases in Hyderabad.

Let’s explore the frequently utilized metal welding system landscape and how SV Interiors integrates these technologies into our daily operations.

🏗️ What is a Metal Welding System?

A metal welding system refers to a set of tools, machines, and techniques used to join two or more metal components by applying heat, pressure, or filler materials. The result is a single, cohesive structure that is strong, stable, and often permanent.

These systems are essential in industries such as:

- 🏠 Interior design & custom furniture

- 🏢 Commercial fit-outs

- 🛠️ Civil construction

- 🚗 Automotive & transport

- ⚙️ Manufacturing & fabrication

In the context of interior work at SV Interiors, Hyderabad, welding systems are used for:

- Modular kitchen framework

- Wardrobe and shelving reinforcements

- Steel staircase and railing fabrication

- False ceiling grid supports

- Custom decor pieces using iron or steel

🔍 Why Welding Is Crucial in Interior Projects

Before we explore specific types of frequently utilized metal welding systems, it’s important to understand why welding is essential for modern interiors.

✅ 1. Structural Strength

Welded metal joints are often stronger than the base material, ensuring long-term reliability in wardrobes, kitchen racks, railings, and partitions.

✅ 2. Design Versatility

Welding allows for custom curves, arches, and frames that wouldn’t be possible with just screws or rivets.

✅ 3. Space Optimization

Steel and aluminum frames take up less space and offer a more streamlined look, ideal for compact Hyderabad apartments.

✅ 4. Durability & Longevity

Well-welded joints last decades, even in heavy-use zones like modular kitchens or outdoor balconies.

🔩 Frequently Utilized Metal Welding Systems in Interior Design

Let’s now dive into the most frequently utilized metal welding systems across Hyderabad and broader India — especially those used by interior and civil work firms like SV Interiors.

1. MIG Welding (Metal Inert Gas Welding)

Also known as: GMAW (Gas Metal Arc Welding)

Used For: Furniture frames, steel décor, light structural work

✅ Easy to automate

✅ Fast and clean

✅ Best for thin to medium gauge metals

Why SV Interiors Uses It:

For mass production of metal parts, MIG welding offers quick, efficient joints with minimal spatter — ideal for pre-fabricated furniture or modular setups.

2. TIG Welding (Tungsten Inert Gas Welding)

Also known as: GTAW (Gas Tungsten Arc Welding)

Used For: Stainless steel decor, aluminum panels, precision work

✅ Cleanest welds

✅ Great for delicate jobs

✅ High-end finish quality

Why SV Interiors Uses It:

For high-end interior decor items and modern staircases in Hyderabad’s luxury homes, TIG welding provides a seamless finish with zero splatter.

3. Stick Welding (Shielded Metal Arc Welding – SMAW)

Used For: Heavier construction, steel reinforcements, civil structures

✅ No need for shielding gas

✅ Works well outdoors

✅ Handles rusted or painted metals

Why SV Interiors Uses It:

In civil construction work — such as gate fabrication, parking shed frames, and heavy furniture — stick welding offers the most practical and cost-effective solution.

4. Spot Welding

Used For: Sheet metal fabrication, electrical panels, modular kitchen panels

✅ High speed

✅ Minimal heat distortion

✅ Great for mass production

Why SV Interiors Uses It:

For mass-scale kitchen cabinet frames and thin stainless steel sheets, spot welding allows us to create seamless, uniform panels.

5. Flux-Cored Arc Welding (FCAW)

Used For: Outdoor metal work, thick steel joints

✅ Similar to MIG but better for outdoor use

✅ No external shielding gas needed

✅ Penetrates thicker metals

Why SV Interiors Uses It:

When working on rooftops, balconies, or external gates, this method performs better than MIG in Hyderabad’s variable weather conditions.

🧪 Comparative Overview: Most Frequently Utilized Metal Welding Systems

| Welding System | Strength | Clean Finish | Suitability for Interiors | Cost Efficiency |

|---|---|---|---|---|

| MIG | High | Moderate | Very High | High |

| TIG | Very High | Excellent | Premium Projects | Moderate |

| Stick | Very High | Low | Heavy Structures | High |

| Spot | Medium | High | Kitchens, Panels | Very High |

| FCAW | High | Moderate | Outdoors | High |

🏠 Real Use Cases of Welding in SV Interiors Projects – Hyderabad

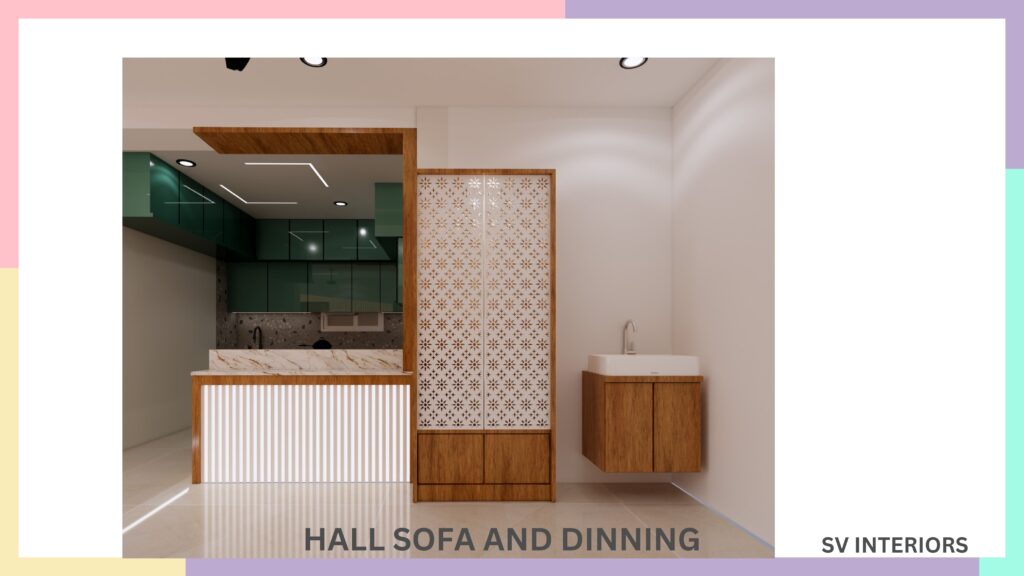

✨ Project 1: Modern Modular Kitchen – Gachibowli

System Used: Spot Welding & MIG Welding

Details:

We fabricated stainless steel carcass frames using spot welding, followed by MIG welding for mounting brackets. Result: Rust-free, long-lasting, and smooth finish.

✨ Project 2: Duplex Staircase Railing – Jubilee Hills

System Used: TIG Welding

Details:

Used TIG welding to build custom spiral stainless steel stair railings. It provided the client a mirror-like polished finish without visible joints.

✨ Project 3: Outdoor Parking Shed – Miyapur

System Used: Stick Welding

Details:

Constructed a heavy-duty MS parking shed frame using Stick Welding to ensure stability and resistance to rain, wind, and weight load.

💬 Expert Opinion: SV Interiors’ Welding Engineers Speak

“Choosing the right welding system can make or break the integrity of your metal structures. At SV Interiors, we always match the method to the metal type, location, and design requirement.”

— Ravi Kumar, Sr. Fabrication Engineer, SV Interiors

🧰 Factors to Consider When Choosing a Welding System

If you’re involved in a home renovation or commercial interior project, you might wonder: Which welding system is best for my job?

Here are five factors to consider:

- Material Type – Mild steel, stainless steel, aluminum, or galvanized?

- Metal Thickness – Thicker metals need deeper penetration methods like Stick or FCAW.

- Location – Outdoor or indoor environment affects shielding gas stability.

- Finish Quality – Decorative items need clean welds like TIG.

- Budget Constraints – MIG and Stick offer speed, TIG offers finesse.

🔒 Safety Practices in Welding: Our Commitment

At SV Interiors, safety is non-negotiable. All welding professionals are trained in:

- Eye and face protection (auto-darkening helmets)

- Fire safety and fume extraction

- Proper grounding and machine calibration

- Handling flammable materials safely

✔️ We follow all BIS, ISO, and local Hyderabad labor safety regulations.

🛠️ How SV Interiors Uses Welding Systems for Custom Furniture

Here’s how frequently utilized metal welding systems directly impact your home or office furniture:

- Bed Frames: Stick-welded MS frames ensure long life.

- TV Units: Spot-welded for sleek, modern appeal.

- Dining Tables: MIG welded legs with powder coat finishes.

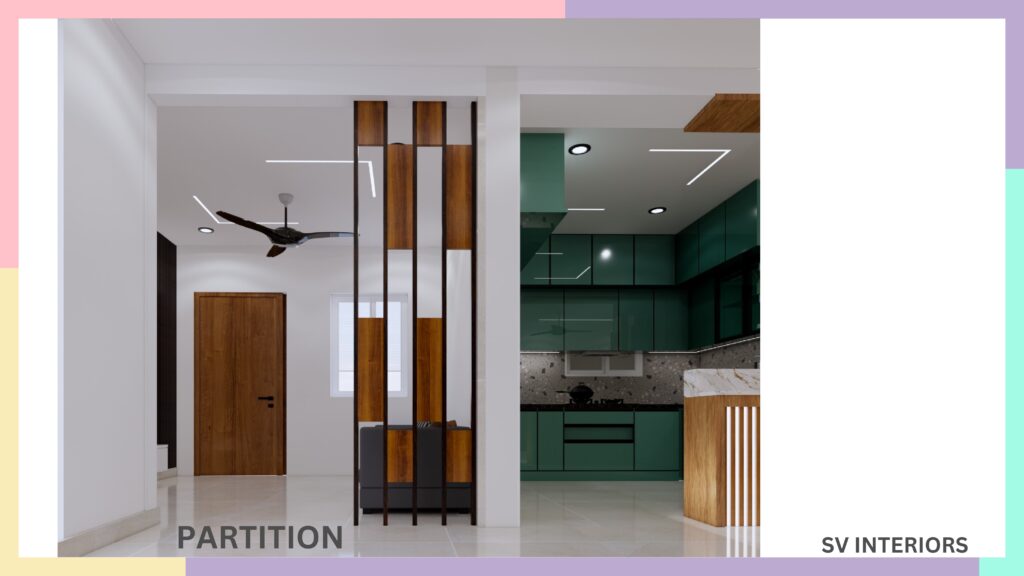

- Custom Partitions: TIG-welded stainless-steel dividers for aesthetics.

- Modular Shelves: Spot-welded MS channels for load-bearing durability.

All products are designed, welded, painted, and installed in-house — reducing cost and increasing quality control.

🌐 Why SV Interiors is Hyderabad’s Most Trusted Metal Fabrication & Interior Partner

Choosing the right welding system is only half the journey. You need a partner who:

- Understands your vision

- Uses quality materials

- Offers full-service design to installation

- Maintains safety and engineering standards

SV Interiors delivers all of this and more — across Hyderabad and Telangana. We blend engineering precision with design creativity, powered by tools like:

- Advanced welding machines (TIG, MIG, Arc)

- CNC cutting & bending

- Powder coating facilities

- AutoCAD & 3D modeling

📞 Ready to Build with the Best?

Whether you’re designing your dream home or setting up a smart office in Hyderabad, SV Interiors offers complete turnkey services, including:

✅ Furniture welding

✅ Modular interiors

✅ Civil construction

✅ False ceiling & partitions

✅ Smart storage designs

Contact us today at 📞 063031 13449 for a free site visit and expert consultation.

🔚 Conclusion: Invest in the Right Metal Welding System for Long-Term Results

To summarize: The frequently utilized metal welding system you choose impacts everything — from aesthetics to strength and safety.

As Hyderabad’s trusted name in interior execution, SV Interiors recommends using the right welding method for the right application — whether it’s MIG for modular kitchens, TIG for decor, or Stick for structural work.

Want to learn more or see live demos of how welding works behind the scenes? Visit our experience center or schedule a project consultation.

Let’s build spaces that last. Let’s weld brilliance into every corner of your home.